How to determine the suitable size of cable for Electrical Wiring Installation

Voltage drop in Cables

We know that all conductors and cables (except Super conductor) have some amount ofresistance.

This resistance is directly proportional to the length and inversely proportional to the diameter of conductor R ∝ L/a [Laws of resistance R = ρ (L/a)]

Whenever current flows through a conductor, a voltage drop occurs in that conductor. Generally, voltage drop may neglect for low length conductors but in a lower diameter and long length conductors, we cannot neglect that voltage drops.

According to IEEE rule B-23, at any point between power supply terminal and installation, Voltage drop should not increase above 2.5% of provided (supply) voltage.

Example: if the Supply voltage is 220V, then the value of allowable voltage drop should be;

Allowable Voltage Drop = 220 x (2.5/100) = 5.5V

In electrical wiring circuits, voltage drops also occur from the distribution board to the different sub circuit and final sub circuits, but for sub circuits and final sub circuits, the value of voltage drop should be half of that allowable voltage drops (i.e. 2.75V of 5.5V in the above case)

Normally, Voltage drop in tables is described in Ampere per meter (A/m) e.g. what would be the voltage drop in a one meter cable which carrying one Ampere current?

There are two methods to define the voltage drop in a cable which we will follow.

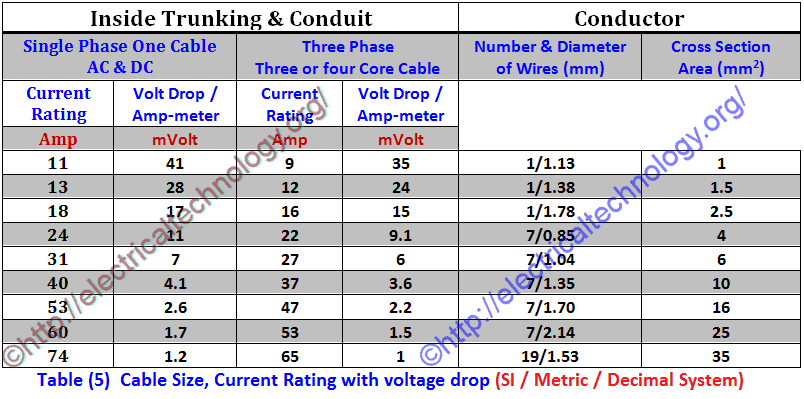

In SI (System international and metric system) voltage drop is described by ampere per meter.

In FPS (foot pound system) voltage drop is described in 100feet.

- Update: Now you can also use the following Calculators to find Voltage drop & the wire size in American wire gauge.

Tables & Charts for Suitable Cable & Wire Sizes

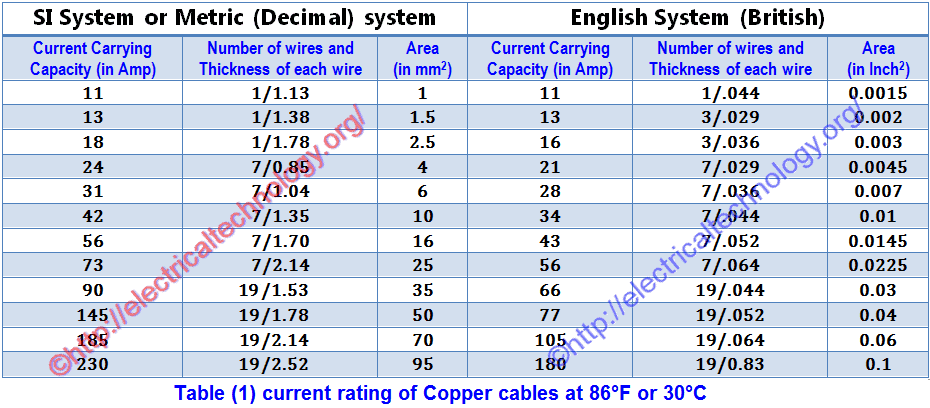

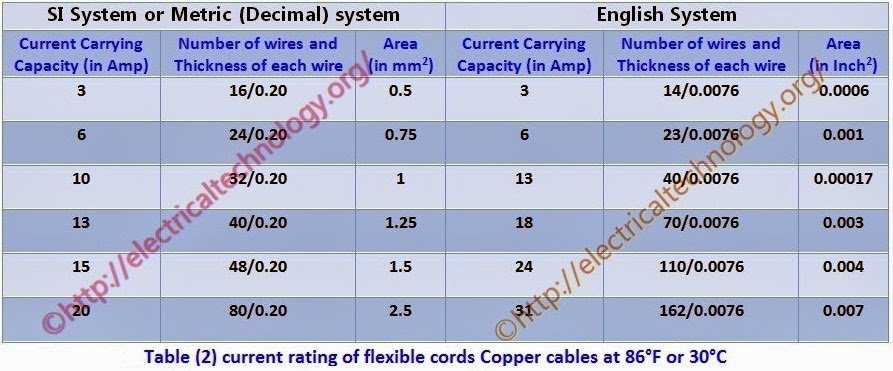

Below are the important Tables which you should follow for determining the proper size of cable for Electrical Wiring Installation.

To find voltage drop in a cable, follow these simple steps

- First of all, find the maximum allowable voltage drop

- Now, Find load current

- Now, according to load current, select a proper cable (which current rating should be nearest to the calculated load current) from table 1

- From Table 1, find the voltage drop in meter or 100feet (what system you prefer) according its rated current

(Stay cool  we will follow both methods and system for finding voltage drops (in meter and 100feet) in our solved example for whole electrical installation wiring).

we will follow both methods and system for finding voltage drops (in meter and 100feet) in our solved example for whole electrical installation wiring).

we will follow both methods and system for finding voltage drops (in meter and 100feet) in our solved example for whole electrical installation wiring).

we will follow both methods and system for finding voltage drops (in meter and 100feet) in our solved example for whole electrical installation wiring).- Now, calculate the voltage drop for the actual length of wiring circuit according to its rated current with the help of following formulas.

(Actual length of circuit x volt drop for 1m) /100 —-> to find Volt drop in per meter.

(Actual length of circuit x volt drop for 100ft) /100—> to find volt drop in 100feet.

- Now multiply this calculated value of volt drop by load factor where;

Load factor = Load Current to be taken by Cable/ Rated Current of Cable given in the table.

- This is the value of Volt drop in the cables when load current flow through it.

- If the calculated value of voltage drop is less than the value calculated in step (1) (Maximum allowable voltage drop), than the size of selected cable is proper

- If the calculated value of voltage drop is greater than the value calculated in step (1) (Maximum allowable voltage drop), than calculate voltage drop for the next (greater in size) cable and so on until the calculated value of voltage drop became less than the maximum allowable voltage drop calculated in step (1)

How to determine the proper Cable Size for Given Load (with Examples)

For a given load, cable size may be found with the help of different tables but we should keep in mind and follow the rules about voltage drop.

Determining the size of cable for a given load, take into account the following rules.

For a given load except the known value of current, there should be 20% extra scope of current for additional, future or emergency needs.

From Energy meter to Distribution board, Voltage drop should be 1.25% and for final sub circuit, voltage drop should not exceed 2.5% of Supply voltage.

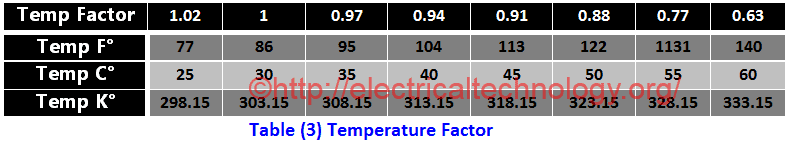

Consider the change in temperature, when needed, use temperature factor (Table 3)

Also, consider the load factor when finding the size of cable

When determining the cable size, consider the wiring system i.e. in open wiring system, temperature would be low but in conduit wiring, temperature increases due to the absence of air.

- Note: Keep in mind Diversity Factor in Electrical Wring Installation while selecting the proper size of cable for electrical wiring installation

Solved Examples of Proper Wire & Cable Size

Following are the examples of determining the proper Size of cables for electrical wiring installation which will make it easy to understand the method of “how to determine the proper size of cable for a given load”.

Example 1 ……….. (British / English System)

For Electrical wiring installation in a building, Total load is 4.5kW and total length of cable from energy meter to sub circuit distribution board is 35 feet. Supply voltages are 220V and temperature is 40°C (104°F). Find the most suitable size of cable from energy meter to sub circuit if wiring is installed in conduits.

Solution:-

- Total Load = 4.5kW = 4.5 x1000W = 4500W

- 20% additional load = 4500 x (20/100) = 900W

- Total Load = 4500W + 900W = 5400W

- Total Current = I = P/V = 5400W /220V =24.5A

Now select the size of cable for load current of 24.5A (from Table 1) which is 7/0.036 (28 Amperes) it means we can use 7/0.036 cable according table 1.

Now check the selected (7/0.036) cable with temperature factor in Table 3, so the temperature factor is 0.94 (in table 3) at 40°C (104°F) and current carrying capacity of (7/0.036) is 28A, therefore, current carrying capacity of this cable at 40°C (104°F) would be;

Current rating for 40°C (104°F) = 28 x 0.94 = 26.32 Amp.

Since the calculated value (26.32 Amp) at 40°C (104°F) is less than that of current carrying capacity of (7/0.036) cable which is 28A, therefore this size of cable (7/0.036) is also suitable with respect to temperature.

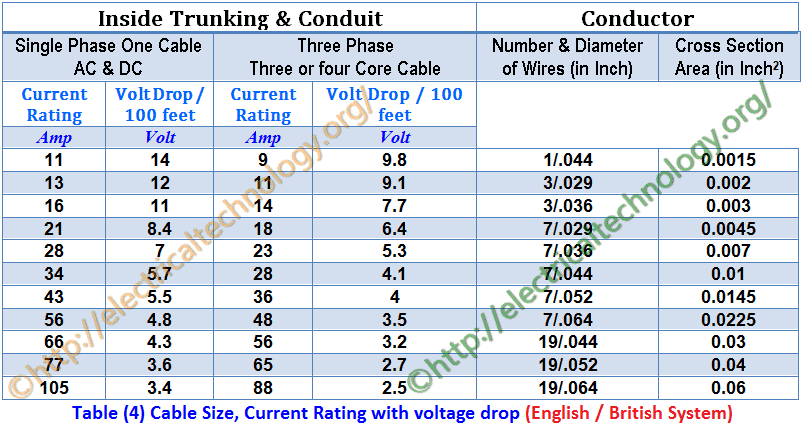

Now find the voltage drop for 100feet for this (7/0.036) cable from Table 4 which is 7V, But in our case, the length of cable is 35 feet. Therefore, the voltage drop for 35feet cable would be;

Actual Voltage drop for 35feet = (7 x 35/100) x (24.5/28) = 2.1V

And Allowable voltage drop = (2.5 x 220)/100 = 5.5V

Here The Actual Voltage Drop (2.1V) is less than that of maximum allowable voltage drop of 5.5V. Therefore, the appropriate and most suitable cable size is (7/0.036) for that given load for Electrical Wiring Installation.

Example 2 ……. ( SI / Metric / Decimal System )

What type and size of cable suits for given situation

Load = 5.8kW

Volts = 230V

Length of Circuit = 35meter

Temperature = 35°C (95°F)

Solution:-

Load = 5.8kW = 5800W

Voltage = 230V

Current = I = P/V = 5800 / 230 = 25.2A

20% additional load current = (20/100) x 5.2A = 5A

Total Load Current = 25.2A + 5A = 30.2A

Now select the size of cable for load current of 30.2A (from Table 1) which is 7/1.04 (31 Amperes) it means we can use 7/0.036 cable according table 1.

Now check the selected (7/1.04) cable with temperature factor in Table 3, so the temperature factor is 0.97 (in table 3) at 35°C (95°F) and current carrying capacity of (7/1.04) is 31A, therefore, current carrying capacity of this cable at 40°C (104°F) would be;

Current rating for 35°C (95°F) = 31 x 0.97 = 30 Amp.

Since the calculated value (30 Amp) at 35°C (95°F) is less than that of current carrying capacity of (7/1.04) cable which is 31A, therefore this size of cable (7/1.04) is also suitable with respect to temperature.

Now find the voltage drop for per ampere meter for this (7/1.04) cable from (Table 5) which is 7mV, But in our case, the length of cable is 35 meter. Therefore, the voltage drop for 35 meter cable would be:

Actual Voltage drop for 35meter =

= mV x I x L

(7/1000) x 30×35 = 7.6V

And Allowable voltage drop = (2.5 x 230)/100 = 5.75V

Here the actual Voltage drop (7.35V) is greater than that of maximum allowable voltage drop of 5.75V. Therefore, this is not suitable size of cable for that given load. So we will select the next size of selected cable (7/1.04) which is 7/1.35 and find the voltage drop again. According to Table (5) the current rating of 7/1.35 is 40Amperes and the voltage drop in per ampere meter is 4.1 mV (See table (5)). Therefore, the actual voltage drop for 35 meter cable would be;

Actual Voltage drop for 35meter =

= mV x I x L

(4.1/1000) x 40×35 = 7.35V = 5.74V

This drop is less than that of maximum allowable voltage drop. So this is the most appropriate and suitable cable or wire size.

Example 3

Following Loads are connected in a building:-

Sub-Circuit 1

- 2 lamps each o 1000W and

- 4 fans each of 80W

- 2 TV each of 120W

Sub-Circuit 2

- 6 Lamps each of 80W and

- 5 sockets each of 100W

- 4 lamps each of 800W

If supply voltages are 230V then calculate circuit current and Cable size for each Sub-Circuit?

Solution:-

Total load of Sub-Circuit 1

= (2 x 1000) + (4 x 80) + (2×120)

= 2000W + 320W + 240W = 2560W

Current for Sub-Circuit 1 = I = P/V = 2560/230 = 11.1A

Total load of Sub-Circuit 2

= (6 x 80) + (5 x 100) + (4 x 800)

= 480W + 500W + 3200W= 4180W

Current for Sub-Circuit 2 = I = P/V = 4180/230 = 18.1A

Therefore, Cable suggested for sub circuit 1 = 3/.029” (13Amp) or 1/1.38mm (13Amp)

Cable suggested for Sub-Circuit 2 = 7/.029” (21Amp) or 7/0.85mm (24Amp)

Total Current drawn by both Sub-Circuits = 11.1A + 18.1A = 29.27

So cable suggested for Main-Circuit = 7/.044” (34Amp) 0r 7/1.04mm (31Amp)

Example 4

A 10H.P (7.46kW) three phase squirrel cage induction motor of continuous rating using Star-Delta starting is connected through 400V supply by three single core PVC cables run in conduit from 250feet (76.2m) away from multi-way distribution fuse board. Its full load current is 19A. Average summer temperature in Electrical installation wiring is 35°C (95°F). Calculate the size of the cable for motor?

Solution:-

- Motor load = 10H.P = 10 x 746 = 7460W *(1H.P = 746W)

- Supply Voltage = 400V (3-Phase)

- Length of cable = 250feet (76.2m)

- Motor full load Current = 19A

- Temperature factor for 35°C (95°F) = 0.97 (From Table 3)

Now select the size of cable for full load motor current of 19A (from Table 4) which is 7/0.36” (23 Amperes) *(Remember that this is a 3-phase system i.e. 3-core cable) and the voltage drop is 5.3V for 100Feet. It means we can use 7/0.036 cable according Table (4).

Now check the selected (7/0.036) cable with temperature factor in table (3), so the temperature factor is 0.97 (in table 3) at 35°C (95°F) and current carrying capacity of (7/0.036”) is 23 Amperes, therefore, current carrying capacity of this cable at 40°C (104°F) would be:

Current rating for 40°C (104°F) = 23 x 0.97 = 22.31 Amp.

Since the calculated value (22.31 Amp) at 35°C (95°F) is less than that of current carrying capacity of (7/0.036) cable which is 23A, therefore this size of cable (7/0.036) is also suitable with respect to temperature.

Load factor = 19/23 = 0.826

Now find the voltage drop for 100feet for this (7/0.036) cable from table (4) which is 5.3V, But in our case, the length of cable is 250 feet. Therefore, the voltage drop for 250 feet cable would be;

Actual Voltage drop for 250feet = (5.3 x 250/100) x 0.826 = 10.94V

And maximum Allowable voltage drop = (2.5/100) x 400V= 10V

Here the actual Voltage drop (10.94V) is greater than that of maximum allowable voltage drop of 10V. Therefore, this is not suitable size of cable for that given load. So we will select the next size of selected cable (7/0.036) which is 7/0.044 and find the voltage drop again. According to Table (4) the current rating of 7/0.044 is 28Amperes and the volt drop in per 100feet is 4.1V (see Table 4). Therefore, the actual voltage drop for 250feet cable would be;

Actual Voltage drop for 250feet =

= Volt drop per 100feet x length of cable x load factor

(4.1/100) x 250 x 0.826 = 8.46V

And Maximum Allowable voltage drop = (2.5/100) x 400V= 10V

The actual voltage drop is less than that of maximum allowable voltage drop. So this is the most

appropriate and suitable cable size for Electrical wiring Installation of given situation.

----------------------

http://www.electricaltechnology.org/2013/10/How-to-determine-the-suitable-size-of-cable-for-Electrical-Wiring-Installation-with-Solved-Examples-in-both-British-and-SI-System.html

ليست هناك تعليقات:

إرسال تعليق